Cold Water

- There are two 25 gallon integral water tanks under the settees, and two 25 gallon flexible water tanks, one under the forward V-berth, and one under the quarter berth.

- Each tank runs to the cold water manifold in the utility room.

- Each tank is filled individually at the tank.

- the filling port is large enough to reach in and clean the whole tank.

- The water level can (usually) be seen through the clear port.

- The vents are at the ceiling of the V-berth with backflow preventers to keep water from surging up the vent pipes in heavy weather. (From experience)

- The manifold has an input and output side.

- Input comes from each of the tanks

- Output goes to the Hot Water system, head, galley, forward cabin, and spare.

- The water in the system isn't pressurized, but is sucked by individual

pumps at each point of use.

- The head and fwd cabin sink use 12v diaphragm pumps

- The galley uses foot pumps

- Because the system sucks the water it is important that all the water hoses are as low and level as possible.

- It is more difficult to prime because more air has to be sucked out of the hoses

- A leak in one of the hoses will allow air to suck in and cause a noticeable loss of performance in the system before water will leak out

- This minimizes the chance of a leak causing all the water to be pumped out of the tanks.

- A hose bib in the Head can provide 8GPM or up to 30psi of hot or cold water.

- The 12v pumps are turned on at the point of use with timer switches.

- A diverter valve controls selection of hot or cold water at the head and fwd. cabin sinks

- The Galley has a separate foot pump for hot and cold water.

Hot Water

- The domestic hot water is mixed to the selected temperature with a

thermostatic valve in the utility room (controlled from the galley)

before distribution to the points of use.

- This eliminates wasting water while mixing to the right temperature.

- In the head and fwd. cabin sinks, a diverter valve primes the hot water by directing the incoming not-yet-hot water away from the point of use sprayer and into the cold water hose. A few seconds at that setting, and the hot water has traveled from the utility room to the point of use. Setting the diverter back to the sprayer provides adjusted hot water without wasting the water in the pipes.

- The hot water circulation pump pumps the working fluid through the heat exchanger for the fresh hot water. For a small amount of hot water it isn't necessary to turn this pump on.

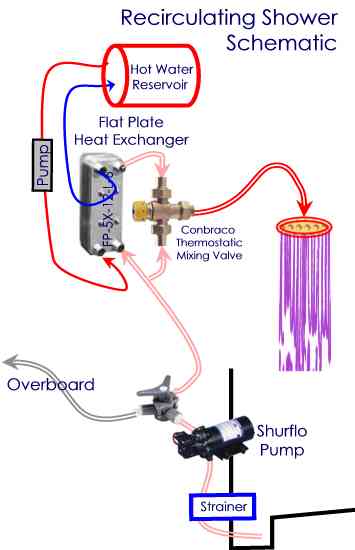

Recirculating Shower

The Recirculating Shower uses about a half gallon of water for a shower of any length. The temperature is controlled by a thermostatic valve, and the heat is extracted from the hot water storage tank. After soaping the used water is discarded.

To take a shower:

- Check that the heat and water breakers on the panel are switched on, and the shower diverter valve is set to "shower"

- Fill the shower sump with fresh water

- Pull the hose off the shower head, turn the shower switch on, and adjust the temperature while the water is circulating.

- Enjoy your shower either from the hose or shower head

- Soap up and rinse off, then direct the soapy water from the hose into the sink to drain the water.

- Use fresh water for a final rinse and drain that water into the sink

- Finally open up the system drain valve to drain the water from the recirculating system

- Wipe down the shower area, sponge out the sump, and clean the lint

filter.

-

The temperature is controlled with the thermostatic valve

-

Heat is extracted from the heat storage system using a flat plate heat exchanger

-

Constant shower temperature requires about 150 btu/min (9000 btu/hr)

-

a fully heated tank will provide about one hour of shower time.

-

-

- When the shower is dry, no shower water remains in the "sump", any pipes, or the heat exchanger

- A diverter valve allows water to be pumped directly overboard

without going through the sink, heat exchanger, or thermostatic valve.

- The thru hull fitting is under the sink and slightly above waterline when the boat is level.

- Maintenance

- From time to time, and before storage, hot chlorinated water should be circulated through the system and rinsed with clean water.

- When there is a noticeable reduction in flow, (about annually) the pump diaphragm or thermostatic valve may need to be be disassembled for cleaning.