Thru Hull fittings

-

Are under the waterline are in compartments that extend above waterline

-

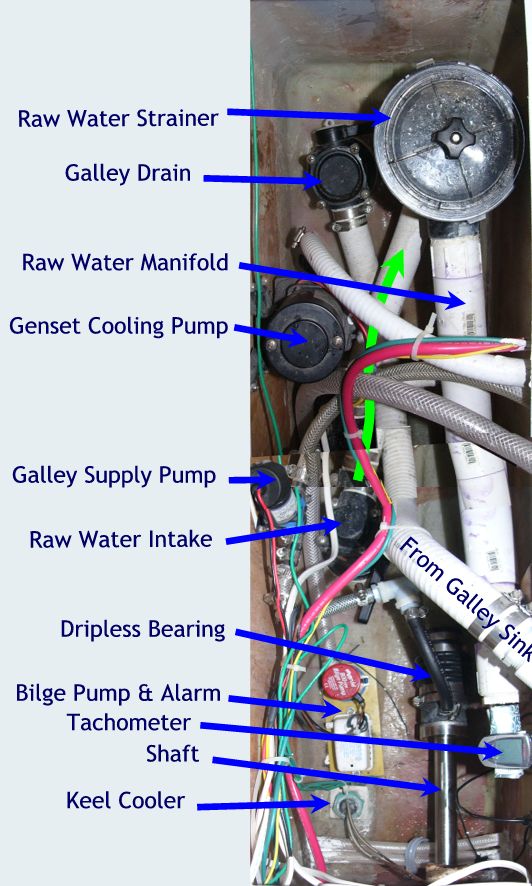

Motor & shaft are mostly under the aft cabin bunk in the shaft compartment. The compartment extends about 4" above the waterline. The shaft uses a dripless shaft seal.

-

Also in the shaft compartment is the drain thru-hull, and a 1.5" inlet thru-hull that is connected to a large strainer and then a supply manifold to supply water for all raw water cooling and watermaker needs.

-

Refrigeration keel cooling block is mounted in the shaft compartment

-

Transducers are in the forward cabin in a compartment that extends 4" above waterline

-

Three other thru-hulls are used for drains, and are located above waterline

Keel

-

draft 5' - 8' (as shallow as 4' in a pinch - rudders extend to 4' )

-

The keel is raised and lowered using a double ended 10:1 block and tackle lifting mechanism led to both of the Harken 46 winches on the cabin top

-

The keel can be adjusted by using either winch, or both simultaneously.

The keel lines are secured with two jammers at each end. One pair are located near the winches, and the other pair on deck near the keel well. Accidentally opening the jammer near the other halyard jammers will not drop the keel because the other jammer can hold the load.

-

A #46 winch, without friction would require 11 lbs of force to turn and about 300 revolutions to lift the keel from 8' to 4'. In reality the force measures at 18 lbs using one winch and about 15 lbs if both winches are in use (the two winches share the friction load)

-

It takes about 6 minutes, including a few rests, to raise the keel.

-

-

Safe design that keeps it from destroying itself or the boat because of operator error.

3 static safety lines keep the keel from dropping out the bottom of the boat if accidentally released. Each one is capable of holding the keel alone. They are slightly different lengths so the dynamic load is taken sequentially.

-

It should not slide up when the boat heals past 90 degrees.

-

There is a pin to secure the keel down when offshore so it can not fall against the hull if the boat turns over in a storm.

-

This could be problematic if the boat grounded with the pin in for two reasons. First the pin could not be removed under load to raise the keel, and second the point loading of a grounding might possibly damage the keel well where the pin is secured.

-

The boat has grounded at 6 kts into a sandbar and 3 kts into rock with no damage to the keel well. When the keel was raised normally with the winches about 3 inches the boat was free.

-

There are two transparent opening ports on the keel well for inspection of the lifting tackle and access to the fuel transfer hoses.

-

The keel is made of mild steel and coated with a layer of glass cloth & epoxy, and then faired and painted. The bulb is cast lead, faired and painted.

The interior of the keel is a fuel tank holding 30 gallons of fuel

-

The fuel filling pipe is at deck level when the keel is at 5' draft level

-

The fuel is removed from the keel with the use of a fuel pump that is attached to the fuel line using quick connect hydraulic fittings. The fuel is transferred to working fuel tanks and the transfer pump is disconnected an put away. The fuel line is accessible through the keel well ports when the keel is at the 6' draft level.

-

Rudders

There are twin rudders with linkage under the deck, a central tiller, and under deck autopilot.

There are deck plates at the end of each rudder shaft where an emergency tiller could be attached

-

There is netting between lazaret storage and rudder linkage to prevent shifting stuff from interfering with steering.

The rudder bearings are UHMW bushings epoxied to the hull bearing against polished stainless bushings on the shaft. Neoprene seals keep water from entering.

-

To remove the rudders release the retaining and linking rings and slide the shaft out. To reinstall, it is necessary to force plastic "hats" into the neoprene seals so the shaft can slide in without damaging them.

-